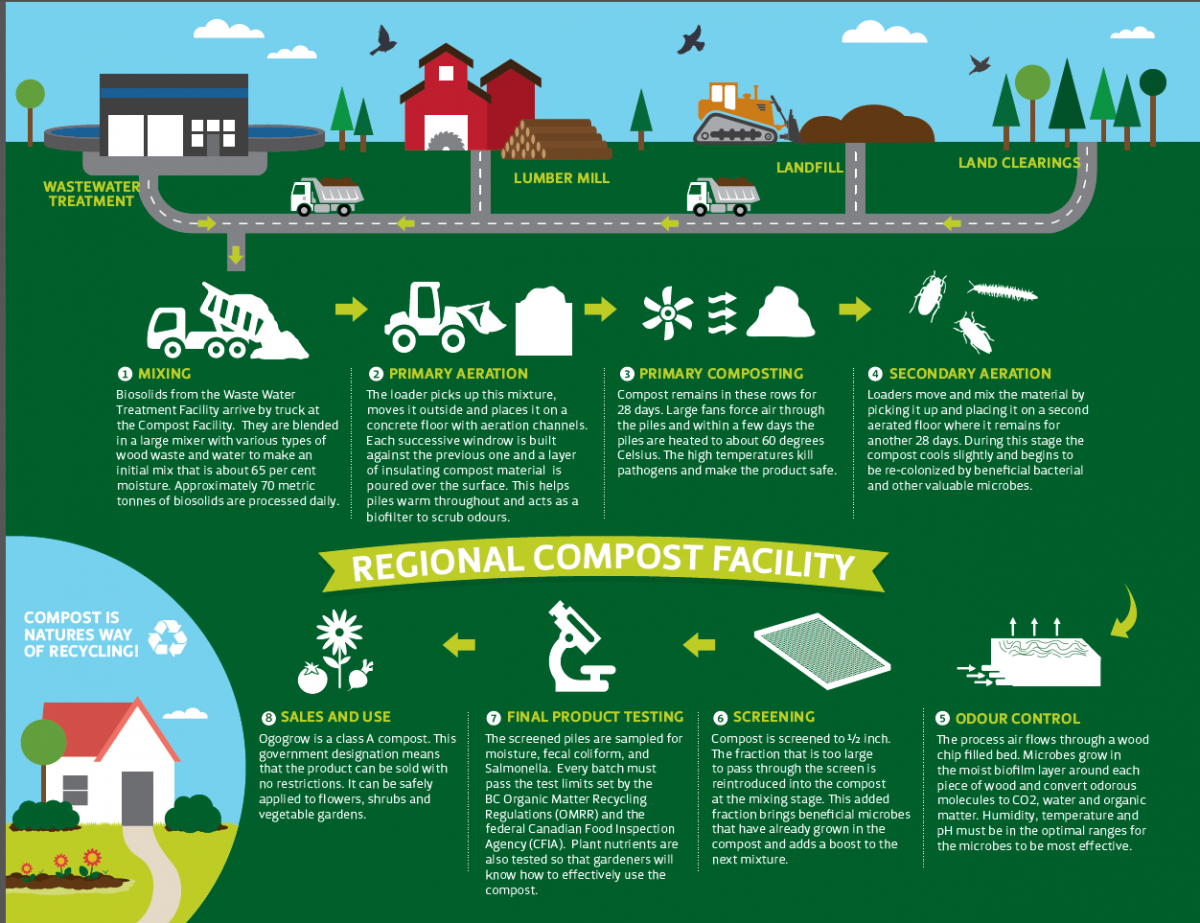

OgoGrow is made by combining biosolids and hog fuel: a byproduct of the local lumber mills. We use an aerobic (with oxygen) treatment process called the Extended Aerated Static Pile Composting Method. Our composting technique allows you to safely use OgoGrow to improve the soil around your flowers, shrubs and vegetable gardens.

We source our biosolids from the wastewater treatment facilities in Kelowna, Lake Country and Vernon. Producing useable biosolids takes numerous processing steps.

Before we get the biosolids, they go through a settling out process called primary treatment. Then the biosolids are biologically reduced by bacteria and other microorganisms that feed on the organic matter (secondary treatment). As the microbes feast on the dissolved and suspended organic matter, it gets incorporated into their cells. Most disease-causing organisms (pathogens) are destroyed during this process. After further digestion or another equivalent treatment, the living and dead microbes form a stable residual we can treat even more.

Properly treating these residuals creates material recognized by the international scientific community as biosolids. When it reaches this refined stage, the product is trucked to the Regional Compost Facility at 551 Commonage Road near Vernon for further processing.

At the Regional Compost Facility, the biosolids are mixed daily with wood waste (hog fuel) from the local forest industry. The initial mix is placed on a large concrete "floor" that has openings through which air is blown into the piles. After the pile is built, a layer about a foot thick of previously composted material is poured over the surface. These insulated piles ensure complete composting and act as a biofilter to help remove unpleasant odours.

Each pile has two temperature probes placed inside. They provide a constant stream of temperature data that gets sent to a computer, which then controls the rate and direction of air flow through the piles. Composting on the aerated piles for at least 25 days achieves further pathogen reduction. During this time, the temperature must rise above 55 degrees Celsius for at least three consecutive days. In fact, the temperature often rises as high as 65 to 70 degrees Celsius, and often remains in pathogen destruction range for the entire time.

The product is then moved, re-blended and placed on secondary aeration for a further 25 to 30 days.

After these two periods of aeration, the OgoGrow we've made with our composting process is screened to one-half inch in size. Samples are taken and analysed for moisture, fecal coliform, and Salmonella. In order to satisfy the BC Organic Matter Recycling Regulations (OMRR) and the federal Canadian Food Inspection Agency (CFIA), there must be less than 1,000 colony forming units per gram (cfu/g) dry weight of fecal coliforms, and less than three cfu/four g of Salmonella. In simpler terms, it has to pass strict tests and be absolutely safe to use before it can be sold.

OgoGrow consistently meets these strict safety limits. OgoGrow is defined under OMRR as a Class A compost that can be safely applied to flowers, shrubs and vegetable gardens.